Quality &

Certification

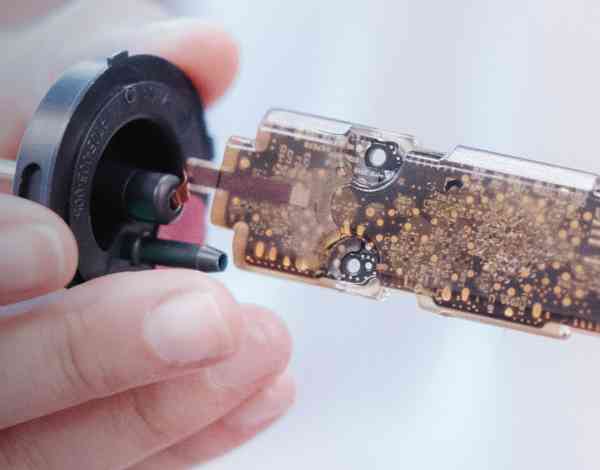

At Sterling, we understand the life-changing potential of the medical devices, equipment and instruments that we manufacture; we also fully embrace the strict, regulatory environments in which they are designed, manufactured and used. Repeatable quality is the key to success, both our clients’ and our own. That’s why we’ve built our entire business around a rigorous and sophisticated Quality Management System, fully integrated into our ERP software with production and change control management, with complete electronic document control.

Our quality assurance process includes a full control plan for Receiving, In-Process and Final Product inspections, and we have a rigorous Product Part Approval Process (PPAP) and First Article (FA) process for new products.

Lastly, our packaging and labelling process is fully integrated into our state-of-the-art ERP system, allowing us to provide our clients with full Serialization and Lot Control tracking.

It all works together to ensure that our clients’ Class I, II & III Medical Devices meet all regulatory requirements, every time. It’s one of the key advantages of working with an experienced contract assembler and manufacturer that specializes in delivering finished and compliant medical devices.

ISO 13485:2016 registered view;

C-TPAT and 21 CFR part 820 compliant; FDA and Health Canada registered facilities

Continuous training and procedural improvement of all our staff to consistently reinforce our Total Quality Environment (TQE)

Continuous Improvement (CI) initiatives in every facet of our organization; Six Sigma certified staff, 5S initiatives

A team of Quality Engineers and Quality Inspectors involved at every step throughout the medical device manufacturing life-cycle

Complete validation of equipment through Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ)

Integrated ERP / MRP / QMS systems for production and change control management

Complete control plans and utilization of Statistical Process Control (SPC)

Advanced metrology capabilities including CMM, Vision Sytems, Optical Comparators, and high precision optical 3D micro measurements.